In any warehouse or loading bay, there’s going to be a lot of heavy lifting to be done. While we might pride ourselves on how much we can carry, when it comes to moving pallets up to a tonne in weight, it’s about time to use some lifting equipment.

If you’re wondering, “what’s the best tool for moving heavy pallets?” then you’re in the right place. At Lifting Equipment Store, we’re here to guide and inform you – so you can feel fully confident in the equipment you use at work.

Hydraulic and winch pallet stackers, or stacker trucks, might be precisely what you need to get things moving in your industry. This article will explain what they are, what they do, and how they could become a vital part of your workplace arsenal.

And if you still have questions by the end of the article, then contact a member of our LES team, and they happily will fill you in on anything else that you’re unsure about.

WHAT ARE STACKER TRUCKS?

Manual pallet stackers are a tool used for the lifting and raising of heavy loads. They can generally carry loads of up to 5 tonnes, making carrying larger items and heavily stacked pallets much easier. Made with either hydraulic pumps or winches, they also allow you to raise these heavy items, generally up to 2850mm (higher on request). Some stackers are even designed to be used together with ladders for loading and unloading to and from higher storage units.

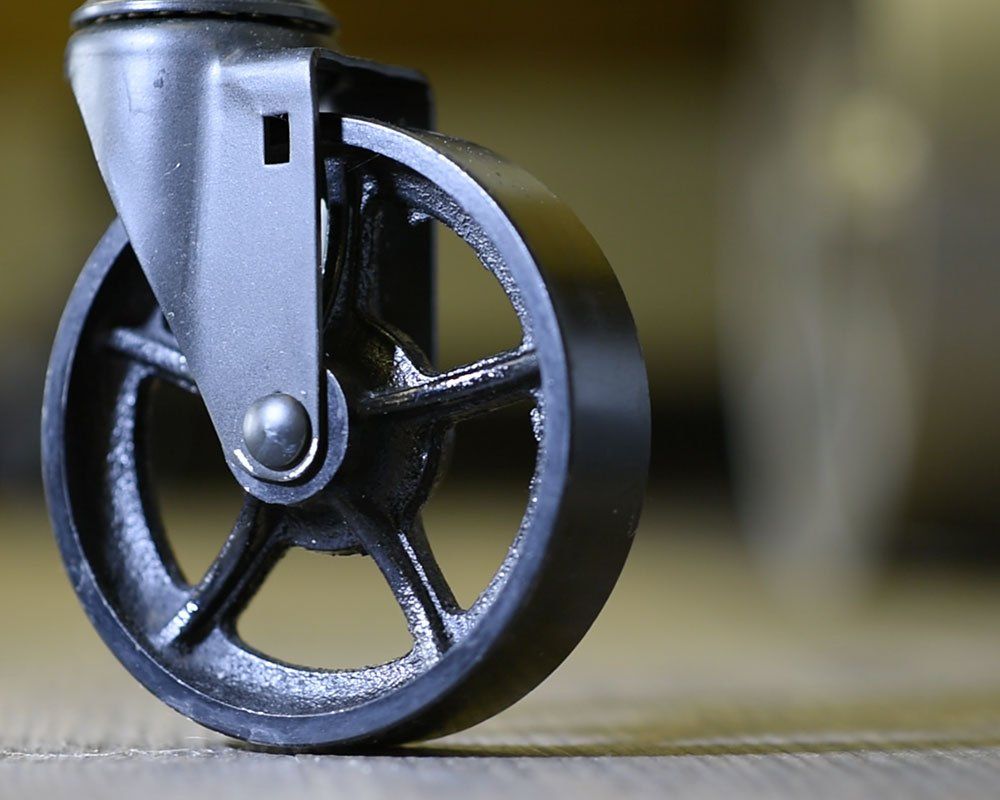

Often stacker trucks will be fitted with smooth steerable wheels, permitting you to transport large items around the workplace with relative ease. These wheels will sometimes be designed with sturdy brakes, giving you total security when you stop to load or unload your stacker.

And then there are Mini Stackers, which generally carry loads of up to 150kg. These can be very handy in work environments that require lots of lighter weight industrial lifting to and from delivery trucks and domestic lifting tasks like moving house.

HOW DO THEY WORK?

Most stackers act much like forklifts, designed with forks that lock into pallets so that you can raise them off the ground. Once the forks are locked into the pallet, or the load is stacked on top of the forks, lifting is achieved through the use of a hydraulic pump or winch.

In a hydraulic manual stacker, you use a pump-activated lever that activates a jack to raise the forks off the ground. The hydraulics in these stackers are optimised by high-quality seal kits that also help keep them safe and secure.

On the other hand, you also have winch-operated pallet stackers. These stacker trucks are operated by turning winches that are attached to either link chains or strong wire cables. A winch pallet stacker can often lift and lower loads quicker than the hydraulic variety, and they are fitted with special brakes to reduce the risk of accidental lowering, giving you complete control.

You can also get stackers with tables in place of the forks, offering a larger surface area onto which you can load items, some of which use scissor lift mechanisms. However, they can also be a little trickier when handling pallets, as forks can make purchases in the gaps between planks that tables cannot.

It’s also worth noting that some stacker trucks are semi-electric, doing the hard part for you and making lifting easier than ever.

LET’S LOOK AT SOME EXAMPLES

Now that you have a handle on what a stacker truck is and how it works, it’s time to look at some of the ones we offer. It’s all well knowing what a tool does, but a picture can paint a thousand words.

Here we have compiled a few examples of both hydraulic and winch pallet stackers, featuring a few key details about each of them.

LS MINI STACKER WITH ADJUSTABLE FORKS & PLATFORM

Key Features:

Ideal for loading and unloading from shelves, vans, cars, and trucks

80kg or 150kg available capacity

Winch operated

LES HYDRAULIC HAND STACKER TRUCK

Key Features:

Controlled lowering

500kg-1000kg available capacity

Hydraulics can be operated with both foot and hand pump

LES SEMI-ELECTRIC HYDRAULIC HAND STACKER

Key Features:

Electric lift functionality

1000kg capacity

Adjustable forks

SAFETY PRECAUTIONS TO TAKE WHEN USING

Now that you know what a stacker truck does, how they work, and what you’re looking for, it’s important to understand how to use one safely.

Here are 5 key tips for safe stacking!

1. Make sure the truck is in order – look for signs of wear and tear to ensure safety.

2. Avoid ramps – carrying heavy loads up and down ramps can lead to accidents, so avoid them when you can!

3. Pull rather than push – pulling allows for better control over your truck.

4. Follow the load limit – the capacity is there for a reason, so don’t overload your stacker.

5. Use your brakes – again, they are there for a reason, so don’t feel the need to rush.

IS IT A SUITABLE SOLUTION FOR YOU?

Now that you understand what a stacker truck is, what they do, how they do it, and how to use them safely, it’s time to decide for yourself if it’s what you need.

Offering easy solutions to heavy lifting tasks, pallet stackers are a staple in warehouses and workplaces all over the UK. If you are dealing with heavy loads regularly, perhaps it’s time to make a move and invest in one.

Other Articles